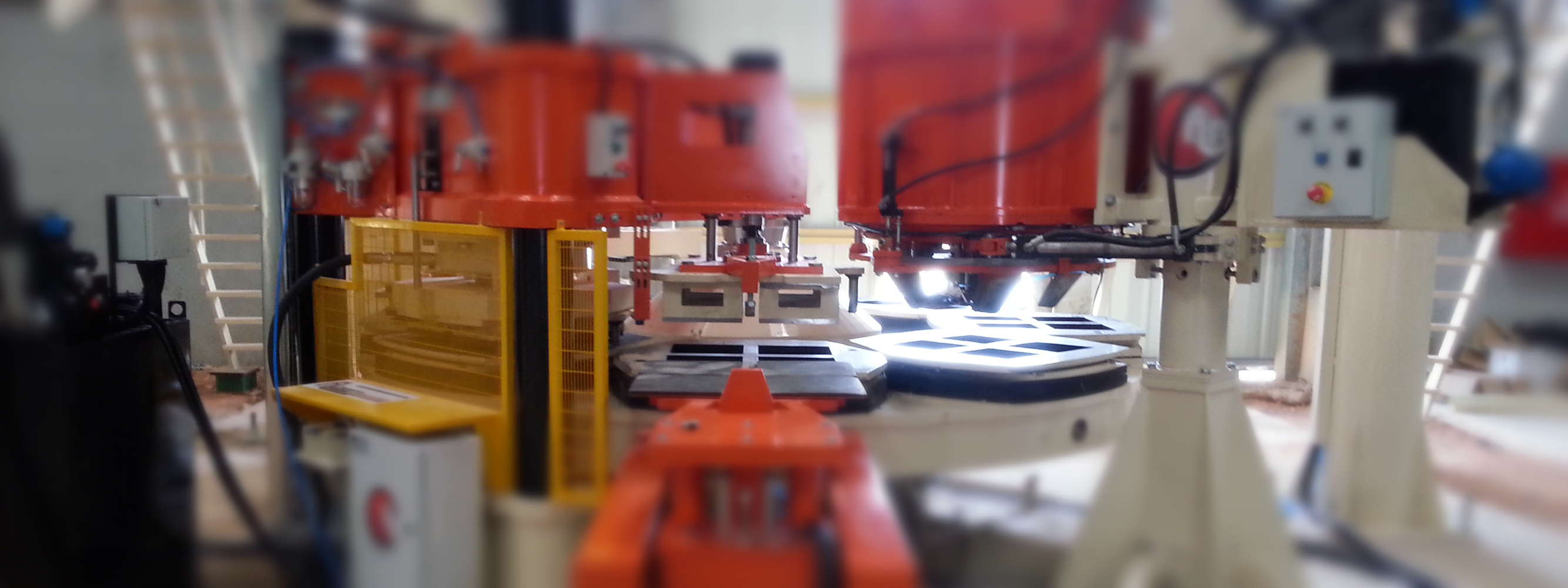

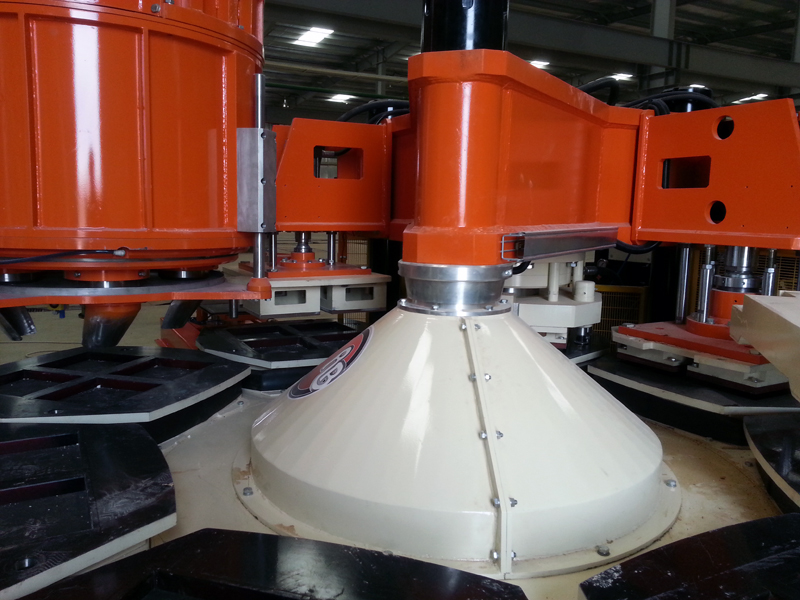

Automatic Rotary Press

Company Production

Production Machinery

Machinery Contacts

Contacts

Model RIBA 208 / 350T

Machine with 8 stations, extremely compact, high-speed, suitable for the production of traditional grit tiles of reduced thickness, mosaic tiles and special raised tiles.

The maximum height of tile to be manufactured is 60 mm (80-100 mm as optional). Made up of a main electric welded steel frame. It consists of the following main machine components: Table rotation gear-motor, equipped with brushless motor and servodrive allowing fluid and very precise movements during turning table phases. Independent hydraulic unit, sized for 300 bar operating pressure, for feeding the press cylinder, the pre-press cylinder and the demoulding cylinder. Hydraulic demoulding device to allow a more constant extraction of the product from the mould. Self-contained electric motor vibrators for feeding the four vibration stations and levelling the material inside the mould. Automatic dosing unit for preparing the first layer, designed for eliminating all possible division among the components of the mixture. Automatic underlay loader. Rod-crank handling device. Pneumatic screed adjustment. Pick-up device. Motion device rod / crank and slotted link. Pneumatic approach device for fresh product delivery without cracks. Independent main electric panel for managing the machining processes, for manual start and exclusion of production processes and maintenance. PLC operation logic of Siemens or Allen Bradley type. Pneumatic device for control and operation of frame lifting cylinders. In compliance with all the general requirements and EEC directives relevant to operator’s safety and hygiene.