Company

Certification History

History Made in Italy

Made in Italy Services and Assistance

Services and Assistance

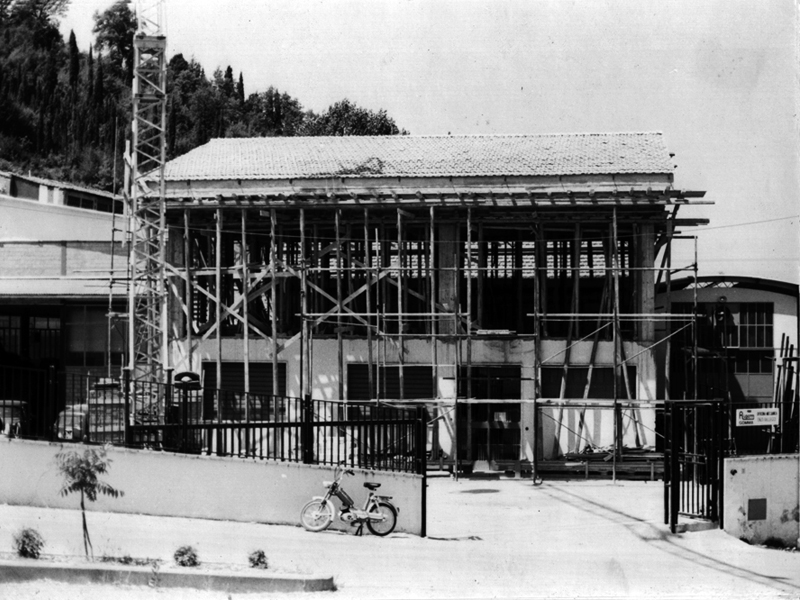

History

1957 Balleggi and Magnolfi; company for manufacturing of mechanical spare parts for cem and grit tile machines on behalf of third party. 1967 Rigam; company exporting spare parts for tiles making machinery. 1973 Rigam and Officina Meccanica Balleggi; companies with separate management in the field of machines producing cem and grit tiles. 1978 Rigam Balleggi S.r.l.; company producing their own products and machines in the files of cement and grit tiles. Small Rotary Press with 4 stations, Bevelling and Washing machines. 1980 Manufacture of spare parts on behalf of a third party for the production and the assembly of high quality precision machining, in the field of Oil & gas, for Nuovo Pignone S.p.a. 1990 Development of machine tools and increasing of machinery for the production of cement and grit tiles. Rotary Press 4 and 6 station. Alternative Press 1 and 2 station. Grinder and Calibrating machine. 2001 Certification of their own Quality System according to ISO 9001:94 standards. 2009 Customized machines and Automatic plant for the production of cem and grit tiles. 2010 Cooperation with General Electric for the production of gas and steam turbine components in the Oil & Gas sector. 2012 High production Machinery and Rotary and Alternative Press of great power: 300-600-800 tons.

Made in Italy

All the machines are produced in Italy, in the Florence plant, through machinery and highly specialized operators. The raw and semi-finished materials used, come from Italian suppliers with certification of origin and manufacturing guarantee.

Certified Quality

On 2001 the Company obtained the Certification of their own Quality System according to ISO 9001:94 standards. From 2003 the Company modified the Quality Management System to make it compliant with UNI EN ISO 9001: 2000 and subsequent modifications. Systematic management of company processes and continuous monitoring of production processes. All the machines produced for the international market are internally tested and are CE marked according to the current regulations on safety for operators.

Services and Assistance

"Turnkey" service; preliminary feasibility study of the project. Construction and assembly of machinery; commissioning and start-up. The company puts its experience at the service of customers. It can intervene directly on site to assist the customer in the management and administration of production.

Customization

Adaptation of a machine and of an entire plant according to to the needs of a single customer. Customization of production cycles and final products.