Bevelling Splitting Machine

Company Production

Production Machinery

Machinery Contacts

Contacts

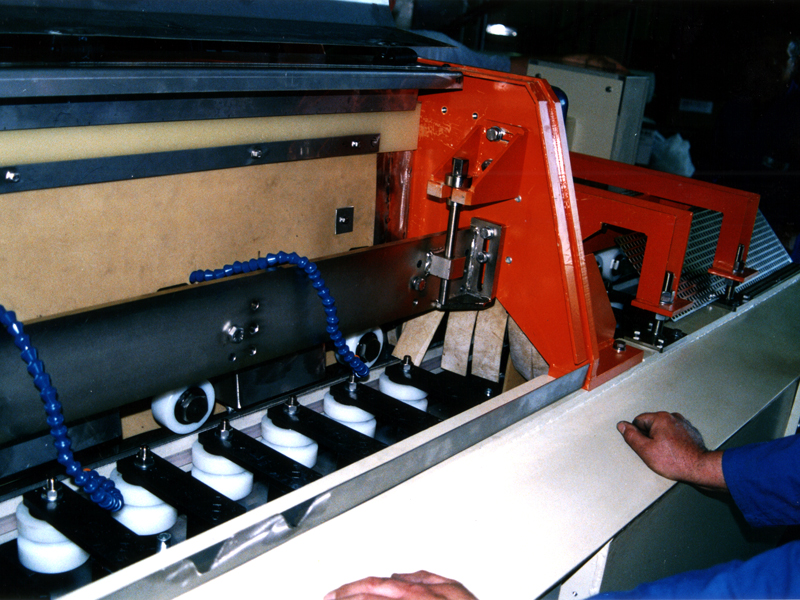

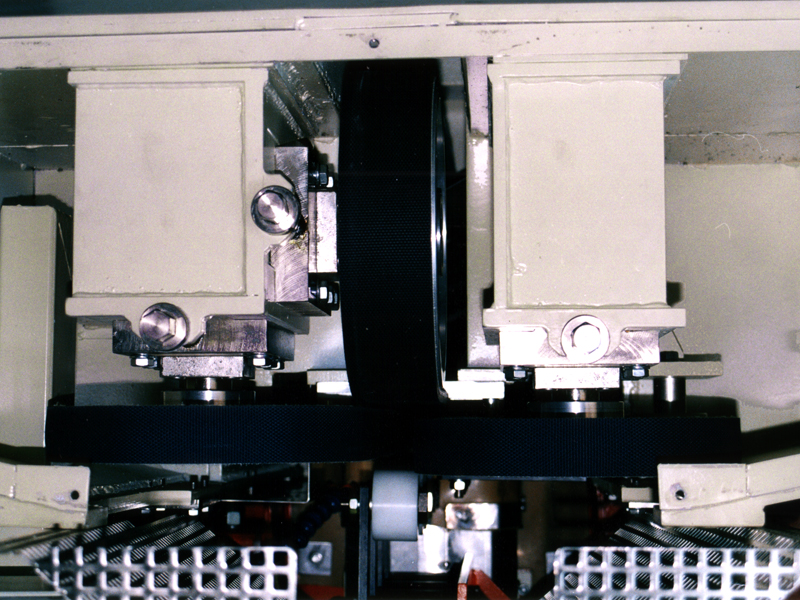

Mod. NBSX100

The Automatic Bevelling Splitting Machine mod. RIBA NBSX100 is conceived to chamfer and split baseboards made from cem and grit tiles cut in several stripes, according to size.

It consists of an electric-welded steel machine bed on which the main machine parts are assembled. The first machine unit houses the control panel and the wheel units, which perform: Height sizing of the tile; Bevel roughing and polishing. The second unit houses the diamond disks for cutting the baseboard in order to make it thinner. Baseboard movement is carried out by 3 conveyor belts running on wearproof guides. Motion is carried out by means of an alternate current inverter gear motor allowing changing the speed of travel, according to the type of material to be machined. Machining is carried out under properly arranged water jets. Regulation of cutting speed by means of inverter gear motor, according to production need and type of material to be machined. Designed and built in compliance with the EEC directives relevant to operator’s safety and health.