Automatic Rotary Press

Company Production

Production Machinery

Machinery Contacts

Contacts

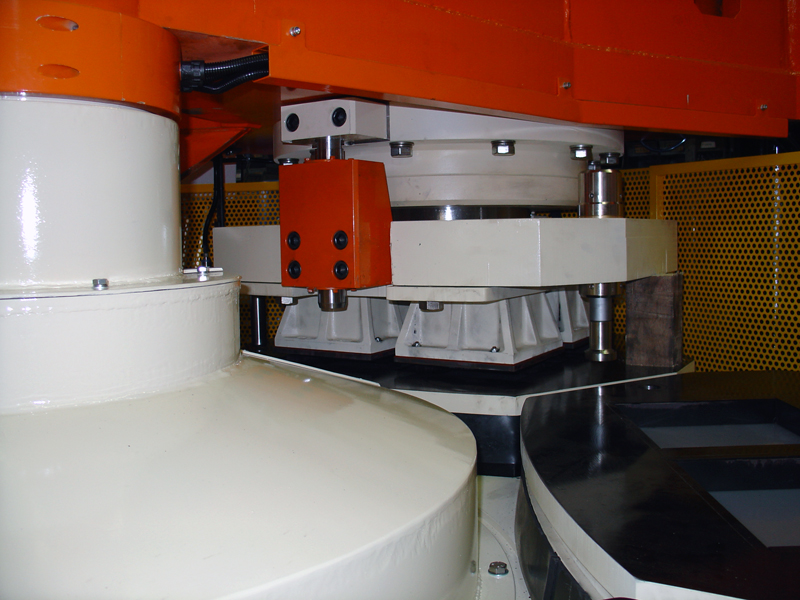

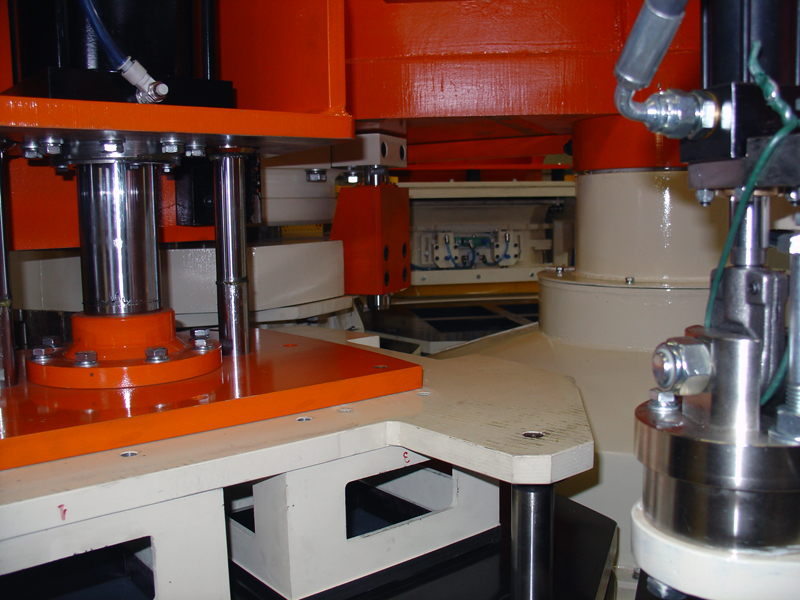

Model RIBA 306

Automatic Rotary Press RIBA 306 with 6 stations, very powerful, suitable for the production of traditional grit tiles, mosaic tiles, special raised tiles and for all other types of cem products.

The maximum height of the article to be manufactured is 60 mm. Made up of a main electric welded steel frame, certified Fe430B, giving the machine sturdiness and withstanding stress. It consists of the following main machine components: Table rotation gearmotor, equipped with brushless motor and servodrive allowing fluid and very precise movements during work phases. Independent hydraulic unit, sized for 250 bar operating pressure, for feeding the press cylinder made from special carbon steel forging. Self-contained electric motor vibrators for feeding the three vibration stations and levelling the material inside the mould. Automatic dosing unit for preparing the first layer, designed for eliminating all possible division among the components of the mixture. Equipped with crown reduction unit allowing continuous and effective mixing. Automatic underlay loader made from electric welded steel. It consists of a main round profile support frame with linear slide guides, on which moves the underlay dosing mechanism. This device is powered by an inverter controlled ratio-motor. Pneumatic screed adjustment for proper cleaning of frame surfaces. Pick-up device consisting of a main frame carrying precision linear guides. These guides make the carriage slide thanks to ball circulation sleeves. On the guides, there is also the trestle with the pick-up units. Motion is performed by an inverter controlled speed-change drive unit, which, connected by means of a mechanical device consisting of connecting rod / crank and slotted link, assures regular and continuous displacement. Pneumatic approach device for fresh product delivery without cracks. Independent monitor for operation process control with touch screen. Independent main electric panel for manual start and exclusion of production processes and maintenance. PLC operation logic of Allen Bradley type. Pneumatic device for control and operation of frame lifting cylinders and product delivery cycle. In compliance with all the general requirements and EEC directives relevant to operator’s safety and hygiene.